Nikka Densok Innovative Vial & Ampoule Combined Headspace Gas Analyzer and Metal Detector Inspection Machine 「2024 Exhibitions」

Hundred percent container closure integrity testing (CCIT)

Annex 1 of Good Manufacturing Practice (GMP) recommendation

When it comes to parenteral injectable drug products, microbial ingress and oxygen exposure contamination inspection is one of the most important steps in the production design process. It is vital for pharmaceutical manufacturers to mitigate such contamination risk vulnerability by including the current CCIT concept during new or existing production line planning.

Moreover, based on the Annex 1 of Good Manufacturing Practice (GMP) recommendation, hundred percent CCIT of parenteral products must be fulfilled before the drug release to the market.

This article introduces a new combined approach that not only can satisfy GMP requirements but also further offers higher level of quality control using a magnetized metal detection functionality.

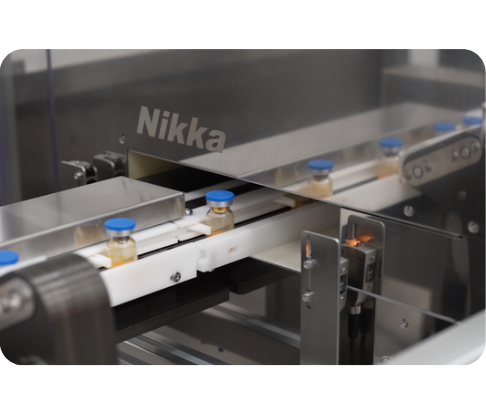

NT-HSGA series vial & ampoule micro leak detection and metal detector

High-speed and reliable inline inspection of vials & ampoules

Among various deterministic and nondestructive CCIT methods recommended by USP1207, laser-based headspace gas analyzer (HSGA) is one of the well-known and mostly used ones. In this way, in an innovative effort, Nikka Densok Japan has developed a new safety and CCIT concept based on HSGA and magnetic metal detector. In a partnership between Nikka Densok and Sweden HSGA instrument manufacturer GASPOROX, we’re happy to announce this new combined machine is now available to the market.

This new machine combines two different pharmaceutical container inspection technologies in order to guarantee the integrity of the container as well as quality of the drug filling processes. The HSGA part inspects the integrity of the container to be free of any micro leak by using an oxygen gas concentration measurement. While, a magnetized metal detector sensor has been deployed to detect any small stainless steel pieces that may have been detached from the filling nozzles or filters.

Features of the NT-HSGA combined machine

- Non-intrusive and non-destructive during production, storage or laboratory use

- Fast and reliable oxygen sensing

- Low headspace measurement

- Eye-safe laser light

- USP1207 recommended

- Speed up to 300pcs/min

- Vial sizes up to 30mm can be inspected

- SUS304 φ 0.2mm × 2mm detection capability

Sensitive and accurate magnetic metal detector

Magnetic metals mixed into the product are magnetized by the magnetic gate on the inlet side of the conveyor. This enhanced magnetic field is then detected by the special magnetic sensor. Although stainless steel is a non-magnetic material, it becomes magnetic metal when cutting, bending or other forces are applied to it during processing or when it is missing. Further, this metal part will be magnetized through the magnetic gate. On the other hand, since aluminum is not magnetized even if aluminum is used for packaging, it is possible to detect only magnetic metals that are mixed without any effect. Hence it is possible the inspect vials with aluminum caps.

Portable and user-friendly HMI management system

This machine offers a portable HMI system which demonstrates all the production, batch, recipe, alarm etc. data in an easy to manage and operate way. Both oxygen concentration as well as metal detection data of each vial will be demonstrated together at the same HMI system. In addition, the metal detector part comes with a separate HMI system which controls the main conveyor setting.

Exhibition at 2024 INTERPHEX WEEK TOKYO & KOREA PACK

The new NT-HSGA machine will be exhibited at INTERPHEX WEEK TOKYO from 26 to 28 June 2024 in booth #38-38, as well as at Korea Pack and ICPI week between 23 to 26 April 2024 in Seoul-at Innotech Systems booth #5A901.

Please visit us to learn more about this new innovation and Nikka Densok other solutions and services.