Nikka Densok All-New Pre-filled Syringe Leak Detection Machine Will Be Exhibited at ACHEMA 2024

Pre-filled syringe container closure integrity testing (CCIT) solution

As the pioneer of high voltage leak detection technology Nikka Densok is presenting all-new pre-filled syringe inspection machine

Pre-filled syringes popularity and demand are increasing among parenteral injectable manufacturers and users due to their advantages compared to vials. Minimizing dosage error, reducing the risk of microbial contamination, quicker and easier preparation for nurses and patients are some of those benefits.

Based on the Annex 1 of Good Manufacturing Practice (GMP), 100 percent CCIT of such parenteral products must be fulfilled during production. Therefore, reliable detection of micro leaks and crack of such pre-filled syringes should take into account as part of the production inspection requirement.

SLD series pre-filled syringe pinhole leak detection

High-speed reliable inline inspection

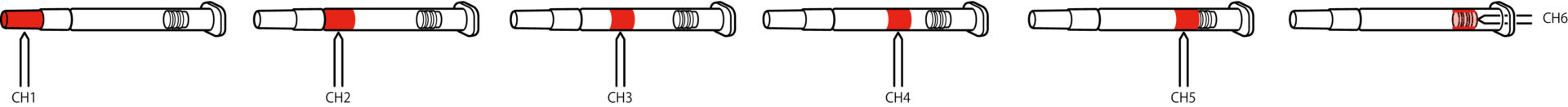

When it comes to micro leak detection of pre-filled syringes, there are five main components: Plunger stopper, barrel, shoulder and needle and needle shield.

Based on the syringe shape, volume and material we offer full-coverage surface inspection using four+ high voltage channels. The SLD series offer up to 600 pcs/min processing capacity for syringe diameters in the range of ø 8.2 – 11mm and can detect pinholes as small as 0.5μm.

21CFR Part 11 & EU GMP Annex1 compliance and USP1207 recommended

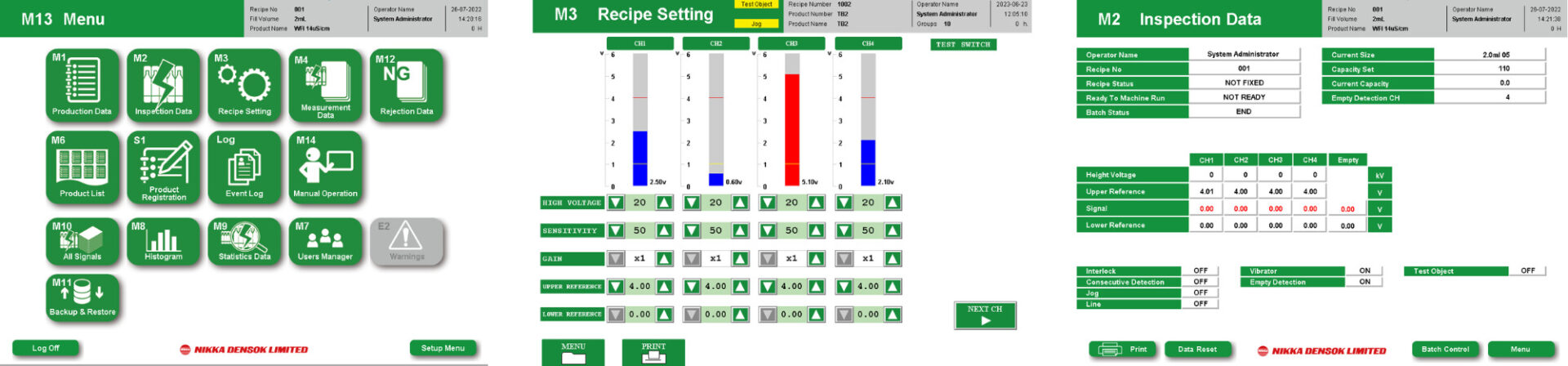

User friendly data management software and human machine interface (HMI) guarantees regulation compliance

Our software and HMI system makes it easy to manage the production data, inspection result data and signal trends with excellent display visibility.

Exhibition at ACHEMA 2024

The SLD series will be exhibited at ACHEMA from 10 to 14 June 2024‐at Nikka Densok stand 3.1/F57 Messe Frankfurt. Please visit us to learn more about our new solutions and services.