High Voltage Leak Detection (HVLD) For Glass Ampoules

Container Closure Integrity Testing (CCIT)

In accordance with Annex 1 of Good Manufacturing Practice (GMP) guidelines, 100% container closure integrity testing (CCIT) is required for ≤100mL parenteral pharmaceutical products before they are released for use. Ensuring the integrity of sterile containers is critical for maintaining product sterility and patient safety.

The USP <1207> guidance on Package Integrity Evaluation – Sterile Products outlines various deterministic and non-destructive methods for CCIT. Among these, High Voltage Leak Detection (HVLD) stands out as one of the most reliable techniques.

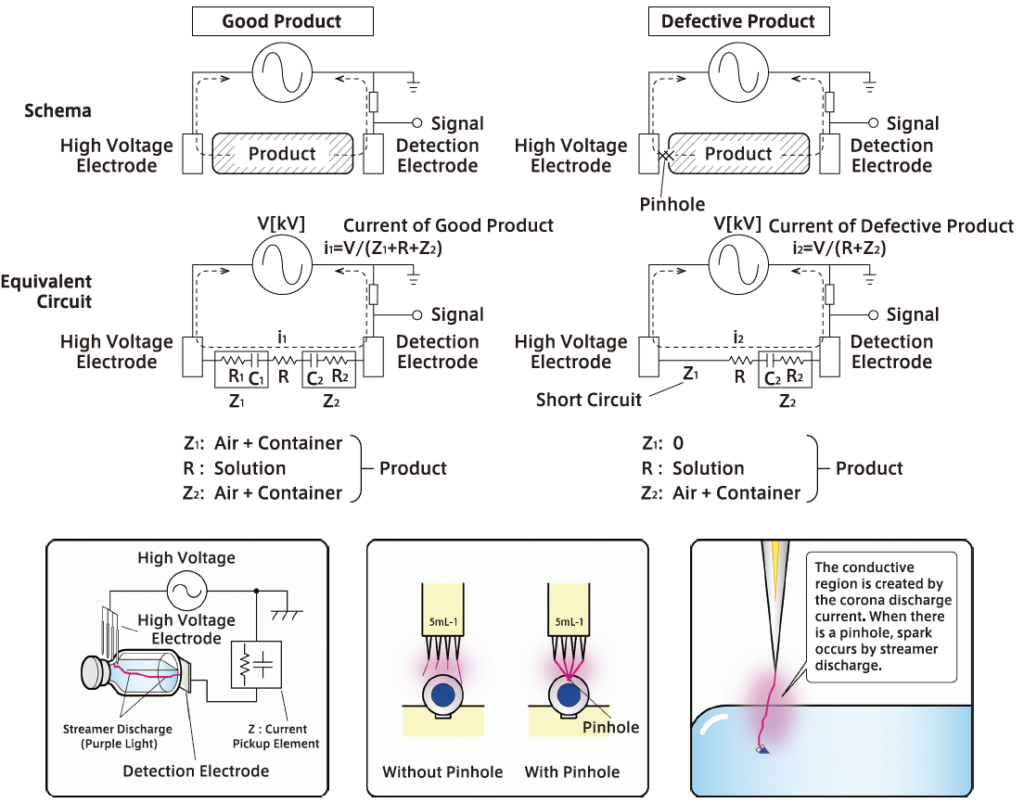

HVLD works by comparing the electrical current between inspection and detection electrodes placed at two points on the container. If a defect is present, the electrical current increases due to a conductive path formed by the liquid inside the container. By detecting and comparing this over-current to the baseline of an intact container, the system can accurately identify and reject defective units from the batch.

Inspection Principle

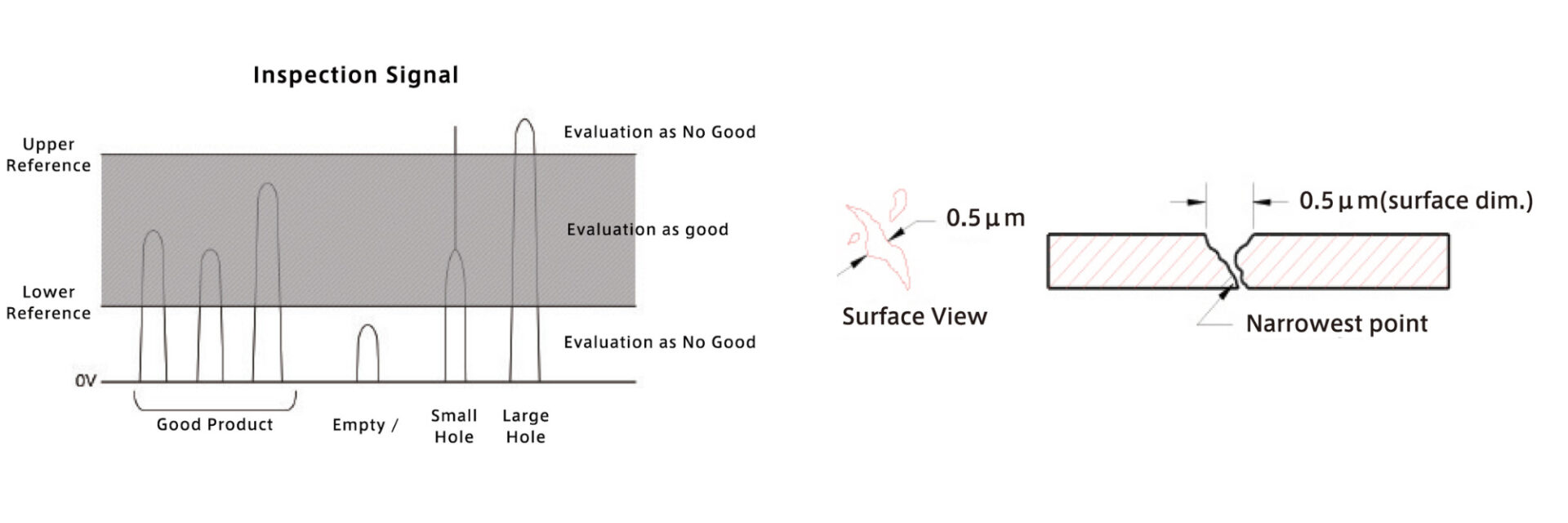

A high voltage (V) is applied through inspection electrodes to a specific area of a sealed container made of non-conductive material. If defects—such as a pinhole, crack, or improper seal—present in the inspection areas of the container, current flows through the compromised area into the solution (R) inside the container. This results in a loss of Z1 resistance, causing a measurable change in current.

By detecting this change, the system can identify the presence of defects. The current is then converted into a readable VDC signal within the electronic circuit and displayed on the operation panel.

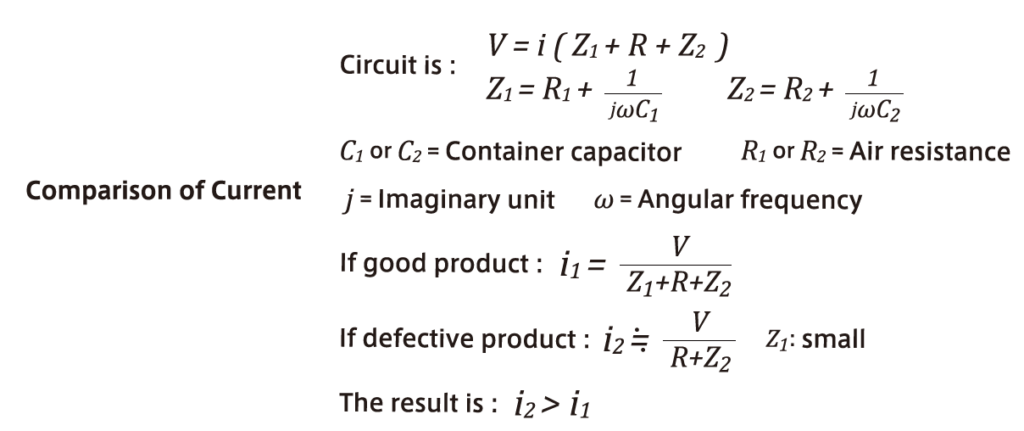

Current Calculation by Equivalent Circuit

Considering the above electrical circuit the good and defective current can be formulated and simplified as follows:

Detection Accuracy

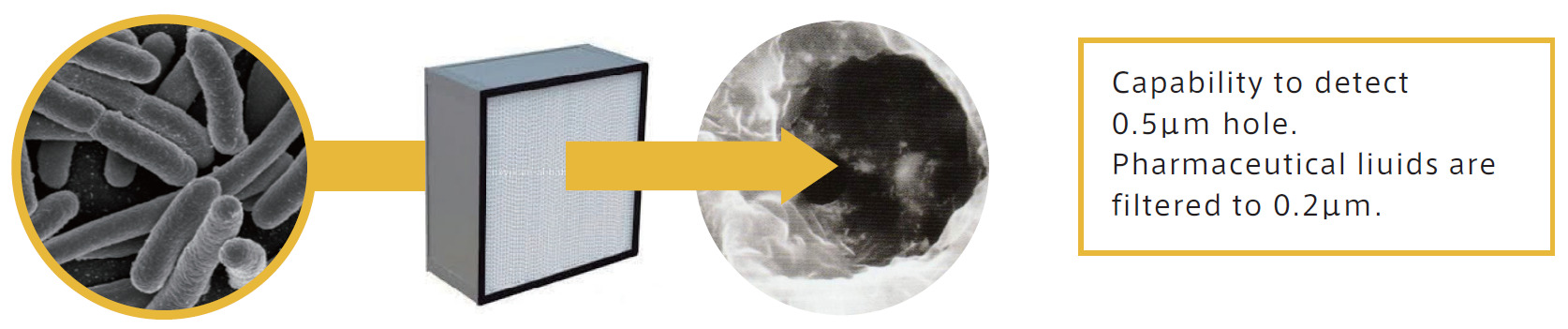

High Voltage Pinhole Inspectors: Ultra-Microscopic Leak Detection

Nikka Densok’s High Voltage Pinhole Inspectors are engineered with advanced technology capable of reliably detecting pinholes as small as 0.1 µm—far beyond the limits of human vision or conventional visual inspection methods.

These microscopic defects are significantly smaller than the 0.2 µm openings typically found in filling filter meshes, ensuring that any potential breach in container closure integrity is identified with precision.

Our Pinhole Inspectors provide a highly sensitive and non-destructive solution for maintaining the sterility and safety of pharmaceutical containers.

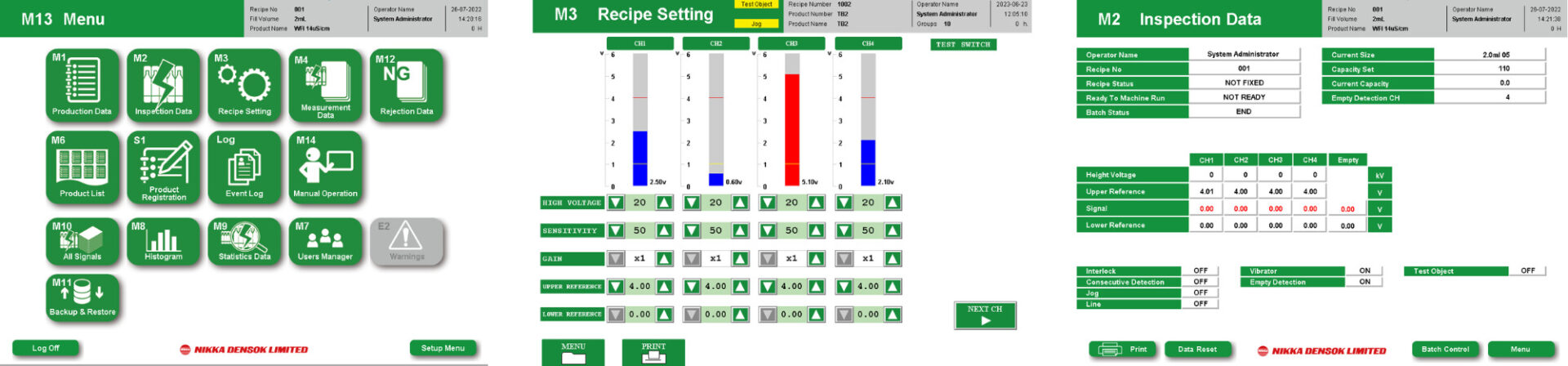

Software & UI

21 CFR Part 11 Compliance

Our user-friendly data management software and intuitive Human-Machine Interface (HMI) ensure easy operation and regulatory compliance. The system provides clear visual displays and allows efficient handling of production data, inspection results, and signal trend analysis.

In line with 21 CFR Part 11 requirements, the software supports multi-level user access management, allowing administrators to define roles and permissions tailored to operational needs.

Additional features include:

• Data transfer and backup via local folders or LDAP integration

• Comprehensive event and alarm logging

• Easy data analysis and report printing through connected printers

Our solutions are designed to simplify compliance, improve traceability, and enhance operational efficiency in regulated environments.

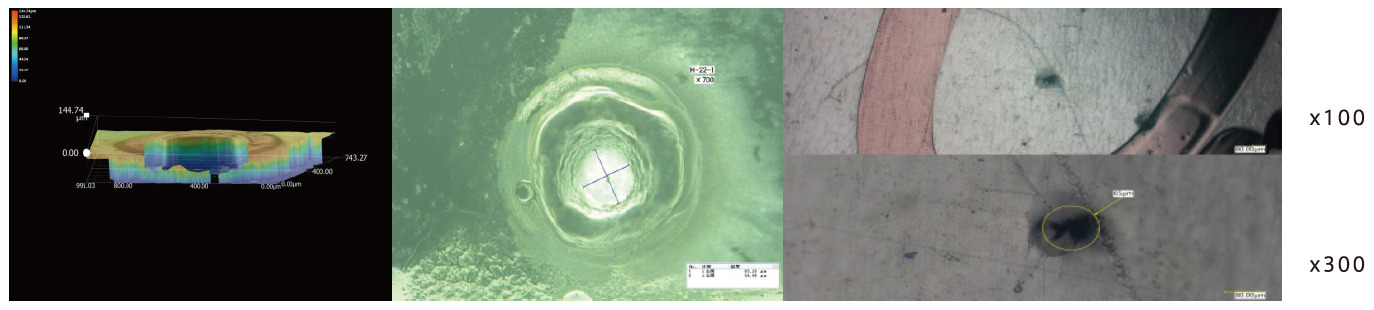

Inspection Performance Validation

Laser-Drilled Micron Hole Detection & Validation Support

Nikka Densok’s inspection systems reliably detect micron-sized holes created through precision laser drilling.

To support customer validation, we collaborate with trusted domestic and international laser processing service providers.

Additionally, our in-house facility is equipped with a KEYENCE laser hole drilling instrument, enabling us to create pinholes as small as 50 μm for testing and demonstration purposes.

This capability ensures effective validation of our leak detection systems and provides customers with confidence in inspection accuracy.

Test Kits for Daily Machine Readiness Checks

Nikka Densok provides customized test kits designed to support daily operational checks and ensure machine readiness before production begins. Each test kit is tailored to match the shape and specifications of the customer’s container.

These kits include components with variable resistance values representing both acceptable and defective products. Arranged according to the machine’s electrode configuration, they allow users to validate proper functioning across the entire inspection process.

By passing the test kits through the system, users can verify:

• Sensor functionality (from infeed to discharge)

• Judgement circuits and inspection components

• Sorting mechanisms

• Signal display and output accuracy

This routine check helps maintain consistent inspection reliability and compliance throughout production.

Equipment Technology

Flexible PLC Compatibility & In-House Electrical Board Development According to UL and CE standards

Nikka Densok supports a wide range of PLC controllers from industry-leading manufacturers such as Mitsubishi Electric, Siemens, and Allen Bradley, giving customers the flexibility to choose electrical components that align with their existing systems and preferences.

In addition, we design and manufacture a variety of in-house electrical boards used within our machines. This not only ensures seamless integration but also provides customers with quick, cost-effective access to spare parts, reducing downtime and maintenance costs.

Our approach offers both customization and convenience to meet diverse operational requirements.

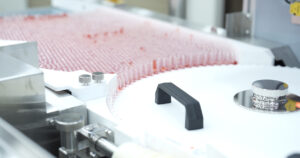

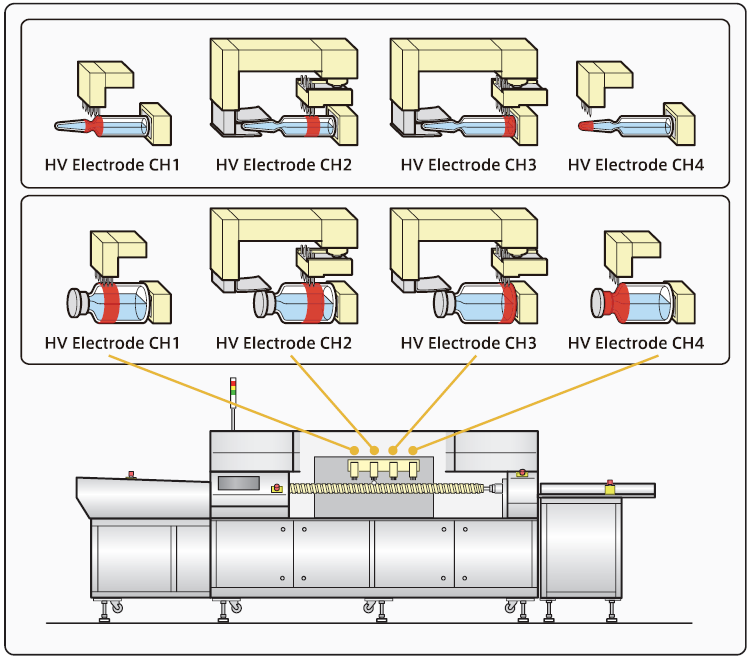

Inline Glass Ampoules CCIT

Nikka Densok Advanced High Voltage Leak Inspection for Glass Ampoule CCIT

Nikka Densok’s advanced high voltage inspection systems are designed to ensure Container Closure Integrity Testing (CCIT) for glass ampoules with high precision and reliability.

This series is equipped with four standard high voltage electrode channels, targeting the most critical inspection points: the tip, neck, body, and bottom of the ampoule. Custom configurations with additional channels are available based on specific product features and inspection requirements.

Each electrode’s inspection range is optimized according to the container’s characteristics, including the electrical conductivity of the liquid inside. Our proprietary electrode design features a unique topology that precisely concentrates the electrical current path to desired areas of the container, allowing for highly targeted inspections.

This innovative approach enables accurate leak detection even in low-conductivity liquids such as Water for Injection (WFI). This machine is capable of detecting leaks as small as 0.1 μm, ensuring the highest level of sterility assurance.

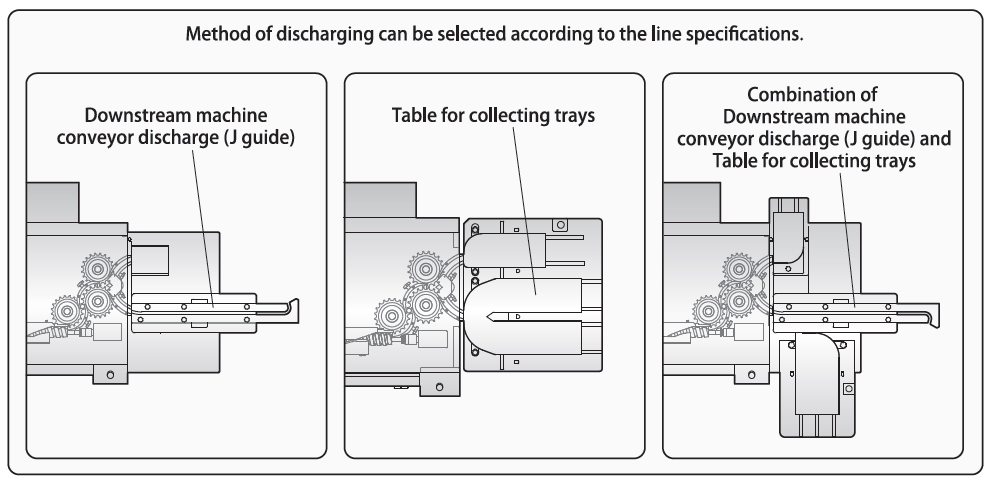

Optional Infeed and Discharge Methods

Customizable Infeed & Discharge Systems for Seamless Integration

Based on the production line layout and the configuration of upstream and downstream equipment, Nikka Densok offers a range of customizable infeed and discharge transportation methods to ensure smooth and efficient integration. Options include:

• J-guides

• Turn-tables

• Robotic handling systems

• Manual tray loading/unloading

Our discharge systems are designed to completely separate good, defective, and uninspected products, eliminating the risk of container mix-up after inspection. This ensures traceability, product integrity, and regulatory compliance throughout the production process.

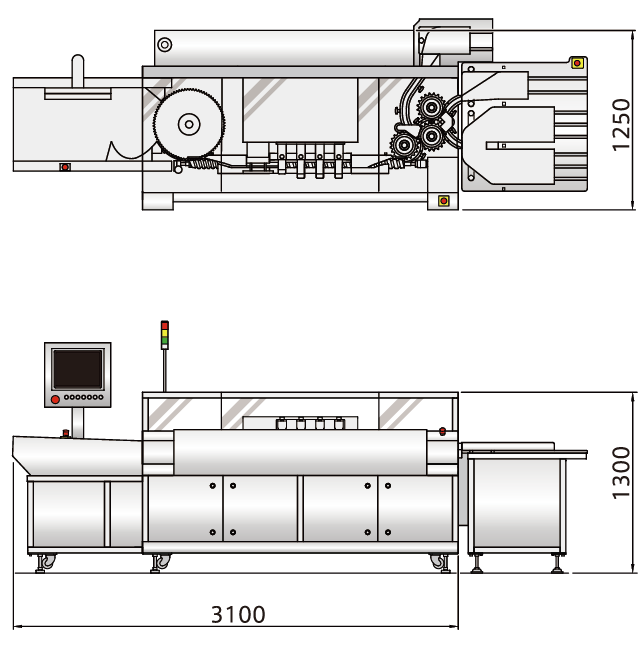

HDB Series Specifications

The following table shows the detail specifications of the HDB-II-ASR series.

| Model | HDB-II-ASR |

|---|---|

| Inspection Station | 4 Channels |

| Processing Capacity | Up to 600 pcs/min (diameter ϕ 10 - 11.75mm) |

| Up to 400 pcs/min (diameter ϕ 11.76 - 18.75mm) | |

| Up to 300 pcs/min (diameter ϕ 18.76 - 22.5mm) | |

| Power Consumption | 5.0kVA |

| Air | 0.5Mpa, 200NL/min |

| Power Supply | 200 - 480VAC. 50/60Hz |